HI 8000 Series

Acid injection/pH control systems

True pH and Alkalinity control solutions for variable flow greenhouse irrigation

HANNA instruments®, the world’s leader in pH technology has worked with leading greenhouses to develop advanced system solutions for covered crops of any type. Each system can precisely control pH and alkalinity from 3GPM up to 200GPM. Incorporating combined pH and flow control technology, the HANNA solution offers features and functionality found no where else in the industry.

Each system can be installed in-tank or directly in-line and is custom configured and programmed to meet the pH and alkalinity requirements of any greenhouse—any crop!

Features

- Quick installation and start up

- Combined pH and flow control technology

- Multiple measuring point monitoring and control from the point of injection to the point of delivery — all from one central controller

- Precise fertilizer control with multiple point EC monitoring

- Maintains selected pH within fluctuating alkalinity and flow rates

- Automatic time or volume control from 8 to 32 zones (solenoid valves)

- 10 easy to use programs for a variety of crops and irrigation timetables

- Programmable starts for “hand watering” or time scheduled activation

- Multiple alarm settings to provide maximum safety and reliability

- PC interface capability for remote monitoring and control

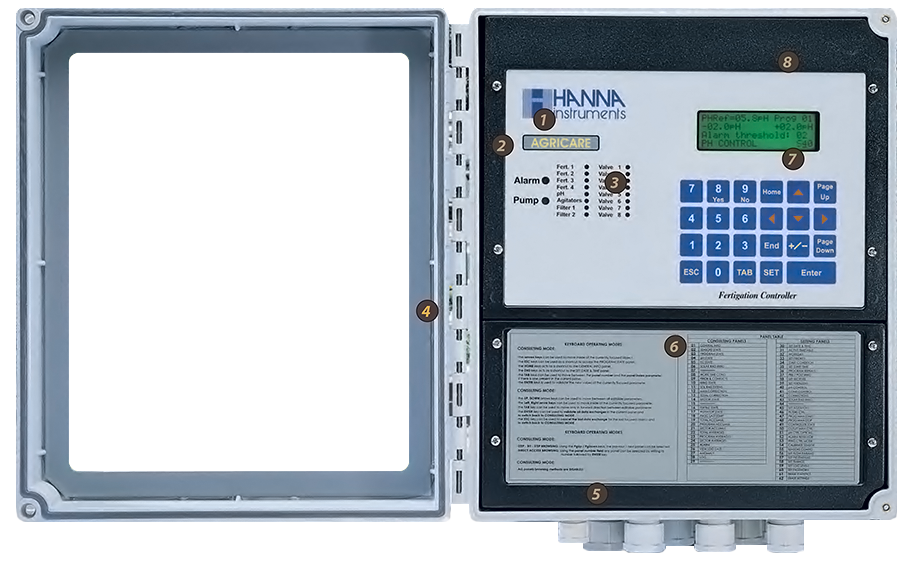

Control Panel

- Fertilizer and acid injection indicators (LEDs)

- Main pump and alarm indicators (LEDs)

- Multiple zone valve indicators (LEDs)

- Waterproof NEMA 4X casing

- Multiple connection ports

- Up to 62 selectable “screens” for readouts and programming

- Touch keypad

- Backlit LCD

- Fertigation (fertilizer and irrigation) controllers

- Time or volume control with up to 10 irrigation programs for up to 32 sectors

- 4 fertilizer dosing control based on EC, volume or ratiometric

- Agitators controlled

- Filter cleaning detection and control

- Up to 2 pH and up to 3 EC probes connected through analog transmitters

- pH and EC reading temperature compensated on

transmitter level

- Solar radiation, wind, temperature sensors

- Power engine back-up management (HI 801X only)

- Mixing input water control (HI 804X, HI 805X)

- Alarms for controlled parameters, water presence, pH or EC out of range and self system diagnostics

- Logging organized on three levels, user selectable

- RS232 connection to PC

Variety and customization of models

A wide variety of models are available to cover the requirements of specific fertigation applications. The HI 8000 series are fully customizable and upgradable on the hardware and program level. HI 8000 series models can be selected based on the irrigation and fertilization type of control along with the additional features that are proper for the specific application. Some of the most important criteria in selection of controller type are: number of irrigated sectors: 8, 16, 24, 32; type of irrigation control: in volume or in time; type of fertilizer control: by EC, by Volume, ratiometric; type of pH correction: acid or alkaline; control of incoming water: one, two or three sources of water; control of dosing with venturi or motorized electrovalves; redundancy of the conductivity or pH probes; mounting solution: panel or wall mounted.

Irrigation control

Irrigation control differs based on the type of control: by irrigation water volume or by irrigation time; the number of sectors that have to be irrigated, the available sources of water for irrigation – one or more with or without reusing the irrigation drain water. Irrigation control is started by opening the irrigation valves and starting the main irrigation pump. The control of all these elements is performed by the controller based on concepts of irrigation programs.

Irrigation programs

Up to 10 irrigation programs can be set by the user with different irrigation parameters: irrigation periods, type of irrigation control, irrigated sectors and volume or irrigation time specified for each sector, conditions to start irrigation such as time, accumulated solar radiation, low level in tanks (hydroponic crops), temperature variations, linked to another program, priority of program, number of repetitions. For irrigation water, each program has a defined pH set point, EC set point (if the quantity of fertilizer is dosed according with conductivity), and receipt of fertilizers. Control of agitators is specified by programs according with the irrigation periods.

Irrigation water

The quality of irrigation water is assured by proper control of pH and the quantity of nutrients (fertilizers) present in irrigation water.

Fertilization control

Fertilizer can be dosed during irrigation using the Venturi tubes principal or with motorized valves. The control of the quantity of dosed fertilizer can be performed using the volume counters. The system supports dosing from up to 4 fertilizer tanks with specific receipts.

The concentration of the fertilizer in irrigation water can be controlled based on the conductivity reading, proportional with irrigation water based on the receipt or ratiometric, in which case the certain quantity of fertilizers are added with the amount of programmed water.

pH control

The pH control is performed in order to adjust the pH of water to the irrigation program set point.

The pH correction can be performed with alkaline or acid solution based on the characteristic of the incoming water.

The control of pH and EC is performed with PID, PI or proportional control. The tuning of the PID control can be accomplished by the user manually, or automatically by the PID auto-tuning feature..

Agitators and filter cleaning

The automatic control of agitators used in fertilizers tanks and filter cleaning system complete the needs of a standard fertigation system.

In order to keep the fertilizer concentration constant before and during the irrigation program, the fertilizers are mixed in their tanks based on the agitators program. The system can manage up to two filters mounted to protect the probes and in-line dosing elements.

With differential presostates, the filters are monitored and when necessary, the irrigation programs are automatically suspended and washer filter cleaning is started. This process removes any deposits and sediments that may appear on filters to increase the systems life.

Redundancy of EC and pH probes

For safety reasons, the systems can be equipped with 2 conductivity probes and two pH electrodes in redundancy so that the system can generate an alarm in the case of reading differences between them. A third conductivity probe can be mounted to verify and compensate the incoming water conductivity.

Logging system

The logging of the controller can be selected on three levels: input reading variations, statistics of reading (average of pH and EC) or events (start of programs, opening valves, …).

Alarm system

The alarms of these systems are related to measured water quality parameters like conductivity and pH: out of range, differential reading between redundant probes; over dosing of conductivity or acid or alkaline correction solution, tanks at low level or no dosing detected by counter movement. Similar alarms can be generated after the units self-diagnostic tests are run.

Sensor connections

All the sensors: EC, pH, temperature are connected to the controller via transmitters.

pH and EC are temperature compensated on the transmitter level. The output of analog transmitters can be calibrated at two points for pH and conductivity. Also, the controller offers a calibration in two points for pH and one point for conductivity.

User interface and digital connection

The user interface is based on an 4 x 20 character line LCD, organized for settings and consultancy. The UI has multi-language support.

The RS232 connection permits the connection to a PC (dedicated PC software HI 800104).

Internal back-up system

The systems internal back-up power system offers a special feature; in the case of losing external power, the controller will stop the irrigations and memorize the irrigation programs that were not performed. The controller will start from the uncompleted programs after power has been restored. The programs will be executed based on their priority level with full respect of the quantity of irrigation water, pH level, and concentration of fertilizers.

Additional features that can be found are control of the external power supply and control of mixing of different water sources (clean water, drain irrigation water).

The HI 8001 and HI 8002 fertigation controllers provide up to 10 programs to irrigate up to 32 sectors using time or volume irrigation control. Each irrigation program has one pH and one EC setpoint. The start condition of the program, the irrigation sectors and the time or volume for each sector are user defined. The irrigation water is pH corrected based on the pH control, with acid or alkaline solution and can contain nutrients for crops based on up to 4 fertilizer receipts. Correction of time or volume of irrigated water can be based on accumulated solar radiation or can be manually requested by user. Agitator control and filter cleaning control are performed automatically. The instruments read up to 3 EC probes, one to verify the incoming water EC, and the other two are in-line redundant for safety to measure the current irrigation water EC. The two pH electrodes are mounted in-line redundant for safety to read the irrigation water pH. The instruments provide an alarm system and logging organized on user selectable three levels.

The HI 8011 fertigation controller provides up to 10 irrigation programs to irrigate up to 16 sectors using volume control. The start condition of the program, the irrigation sectors and the volume for each sector are user defined. The irrigation water is pH corrected based on the pH control, with acid or alkaline solution and can contain nutrients for crops based on up to 4 fertilizer receipts. Fertilizer dosing is performed based on the volumetric control (quantity of fertilizer is dosed in ratio with volume of irrigated water). Another important feature is related to the ability to manage an external back-up power supply. The start of irrigation programs based on the temperature variations (like antifreeze reaction) is also a unique feature offered by this model. Agitator control and filter cleaning control are performed automatically. This instrument provides an alarm system and logging organized on three levels that are user selectable.

The HI 8021 and HI 8022 fertigation controllers provide up to 10 irrigation programs to irrigate up to 16 sectors using time or volume control. Each irrigation program has one pH and one EC setpoint. The start condition of the program, the irrigation sectors and the time or volume for each sector are user defined. The irrigation water is pH corrected based on the pH control, with acid or alkaline solution and can contain nutrients for crops based on up to 4 fertilizer receipts. Fertilizer dosing is performed based on the volumetric control. Additionally, an EC level monitoring/alarm is implemented to stop irrigation should the conductivity exceed the maximum set level in order to avoid damages to irrigated crops. Agitator control and filter cleaning control is performed automatically. The instruments read up to two EC probes redundant in-line for safety to measure the current irrigation water EC. The two pH electrodes are mounted in-line redundant for safety to read the irrigation water pH. The instruments provide an alarm system and logging organized on three user selectable levels.

The HI 8051 fertigation controller provides up to 10 irrigation programs to irrigate up to 24 sectors using time or volume control. Each irrigation program has one pH and one EC setpoint. The start condition of the program, the irrigation sectors and the time or volume for each sector are user defined. The irrigation water is pH corrected based on the pH control with acid or alkaline solution and can contain nutrients for crops based on up to 4 fertilizer receipts. Fertilizer dosing is permormed based on the EC, volumetric or ratiometric control. Another important feature is the correction of irrigated water volume or time based on accumulated solar radiation or manually requested by user. Agitator control and filter cleaning control is performed automatically. The instrument reads up to 3 EC probes, one to verify the water incoming EC, and the other two redundant in-line for safety, to measure the current irrigation water EC. The two pH inputs are mounted in-line redundant for safety to read the irrigation water pH. This instrument provides an alarm system and logging organized on three user selectable levels. An important added feature is this models ability to mix 3 sources of incoming water. Fresh water, reused water and all dosing are performed based on the motorized valves that are activated by motors that allow different flows of the fertilizers, acid and alkaline solutions used for pH correction.

SPECIFICATIONS

| FAMILY | 800X | 80011 | 802X | 8051 |

|---|---|---|---|---|

| Irrigation control | Time/volume control, 10 programs/5 priority levels with up to 99 repetition | |||

| Irrigation start condition | By Time, by solar radiation, by 5 external tank low level | |||

| Fertilization control | By EC | By volume | By volume, the EC monitored | By EC, By volume, Ratiometric |

| Fertilizers | Up to 4 valves | Up to 4 motorized valves | ||

| pH control/correction | Acid or alkaline | Acid or alkaline, by vol. | Acid or alkaline | Acid or alkaline, motorized pump |

| Agitators control | Yes | Yes | Yes | Yes |

| Filter control/cleaning | 2 differential presostate/2 filter cleaning relays | |||

| Fertilizer tank levels/counters control | Level | No | Counters | Level and counters |

| Irrigation counter | Yes | |||

| Acid/Alkaline tank level/counter control | Level | No | Counter | Level and counter |

| EC inputs | Up to 3, 0.0 to 10 mS/cm | No | Up to 2, 0.0 to 10 mS/cm | Up to 2, 0.0 to 10 mS/cm |

| pH inputs | Up to 2, 0.0 to 14.0 pH | nu | Up to 2, 0.0 to 14.0 pH | 1, 0.0 to 14.0 pH |

| Temperature Compensation | EC, pH | EC, pH | EC, pH | |

| Solar radiation input | 1; 0 to 2000 W/m2 | 1; 0 to 2000 W/m2 | 1; 0 to 2000 W/m2 | No |

| Temperature | No | 2 | No | 1 |

| Wind speed | No | Yes | No | No |

| Engine power back-up | No | Yes | No | No |

| Irrigated sectors | Up to 32 | Up to 16 | Up to 16 | PUp to 24 |

| Mixing source of water | No | No | No | Yes, 3 sources |

| PC connectivity | RS 232 | |||

| Alarms | Yes, user selectable levels | |||

| Logging | Yes, three level | |||

| Power Supply | 115V/220 ± 10 % 50Hz/60Hz | |||

| Environment | wall mounted: NEMA 4X specifications | |||

| Dimensions | wallmounted: 280 x 330 x 165 mm (11.2 x 13.2 x 6.6”); panel mounted: 178 x 260 x 116 mm (7.1 x 10.4 x 4.6”) | |||

| Weight | wall mounted: 4.95 Kg (11 lb.); panel mounted: 3.4 Kg (7.5 lb.) | |||

Ordering information

HI 8001-0100U Fertigation controller with priority for pH and EC, panel mount, 8 sectors, English, 115V.

HI 8001-0100D Fertigation controller with priority for pH and EC, panel mount, 8 sectors, English, 230V.

HI 8001-0200U Fertigation controller with priority for pH and EC, panel mount, 16 sectors, English, 115V.

HI 8001-0200D Fertigation controller with priority for pH and EC, panel mount, 16 sectors, English, 230V.

HI 8001-0300U Fertigation controller with priority for pH and EC, panel mount, 16 sectors, English, 115V.

HI 8001-0300D Fertigation controller with priority for pH and EC, panel mount, 16 sectors, English, 230V.

HI 8001-0400U Fertigation controller with priority for pH and EC, panel mount, 32 sectors, English, 115V.

HI 8001-0400D Fertigation controller with priority for pH and EC, panel mount, 32 sectors, English, 230V.

HI 8002-0100U Fertigation controller with priority for pH and EC, wall mount, 8 sectors, English, 115V.

HI 8002-0100D Fertigation controller with priority for pH and EC, wall mount, 8 sectors, English, 230V.

HI 8002-0200U Fertigation controller with priority for pH and EC, wall mount, 16 sectors, English, 115V.

HI 8002-0200D Fertigation controller with priority for pH and EC, wall mount, 16 sectors, English, 230V.

HI 8002-0400U Fertigation controller with priority for pH and EC, wall mount, 32 sectors, English, 115V.

HI 8002-0400D Fertigation controller with priority for pH and EC, wall mount, 32 sectors, English, 230V.

HI 8011-0200U Fertigation controller with flow control (irrigation counter), panel mount, 16 sectors, English, 115V.

HI 8011-0200D Fertigation controller with flow control (irrigation counter), panel mount, 16 sectors, English, 230V.

HI 8021-0200U Fertigation controller with flow control (irrigation counter), pH dosage and EC monitor, panel mount, 16 sectors, English, 115V.

HI 8021-0200D Fertigation controller with flow control (irrigation counter), pH dosage and EC monitor, panel mount, 16 sectors, English, 230V.

HI 8022-0200U Fertigation controller with flow control (irrigation counter), pH dosage and EC monitor, wall mount, 16 sectors, English, 115V.

HI 8022-0200D Fertigation controller with flow control (irrigation counter), pH dosage and EC monitor, wall mount, 16 sectors, English, 230V.

HI 8051-0300U Acid based fertigation controller with dual pH control, differential EC control, actuator control, multiple dosing and irrigation pump control, panel mount, 24 sectors, English, 115V.

HI 8051-0300D Acid based fertigation controller with dual pH control, differential EC control, actuator control, multiple dosing and irrigation pump control, panel mount, 24 sectors, English, 230V.

Required Accessories

HI 98143-22 pH/EC isolated transmitter, 4-20 mA sourcing current output

1 transmitter is needed in configuration with 1 EC probe and 1 pH probe (no probe redundancy feature)

2 transmitters are needed in configuration with 2 EC probes and 2 pH probes (for probe redundancy feature)

3 transmitters are needed in configuration with 3 EC probes and 2 pH probes (for probe redundancy feature and EC water incoming compensation)

Accessories

HI 1001 “flow-thru”, double junction pH electrode with BNC connector and 3 m (10’) cable

1 or 2 electrodes are needed (2 electrodes for probe redundancy feature)

HI 3001 “flow-thru”, 4 platinum ring EC probe with built-in temperature sensor & 3 m (10’) cable

1, 2 or 3 probes are needed (2 for probe redundancy feature),

(3 for probe redundancy feature and EC water incoming compensation)

HI 60542 Electrode Holder for Direct Pipe

Order according with the total amount of ordered probes

HI 800104 Windows compatible PC application

HI 7004L pH 4.01 buffer solution, 500 mL

HI 7007L pH 7.01 buffer solution, 500 mL

HI 7039L 5.00 mS/cm calibration solution, 500 mL

HI 70300L Electrode storage solution, 500 mL

HI 7061L Electrode cleaning solution, 500 mL

HI 710005 115 VAC to 12VDC power adapter

HI 710006 230 VAC to 12VDC power adapter